- Description

- How to Use

- FAQs and Tips

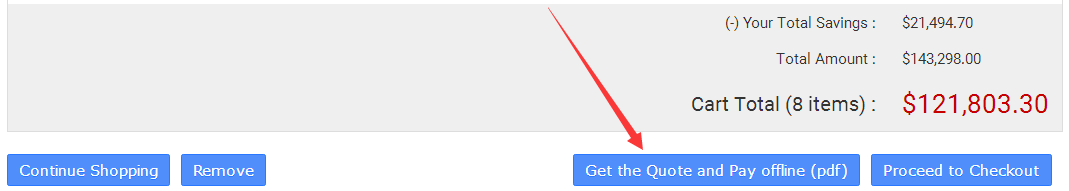

- How to Order

Description:

Portable laboratory testing up to 45,000 psi with electric power.

Application:

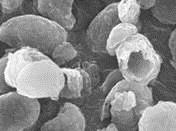

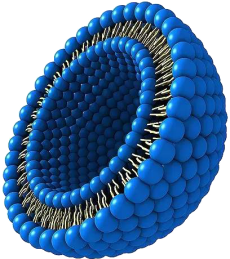

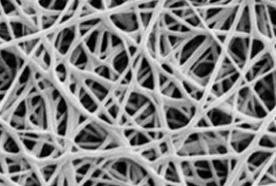

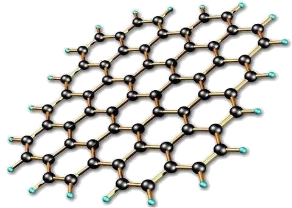

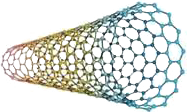

Nanodispersions, nanoemulsions and nanotube

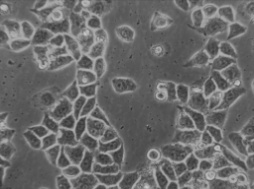

Cell disruption

Micro/nanoencapsulation in polymers, liposomes and oils

Solid dispersion and suspension, deagglomeration

Cell disruption

Micro/nanoencapsulation in polymers, liposomes and oils

Solid dispersion and suspension, deagglomeration

Performance:

Energy-efficient, only 1/2 energy loss of most homogenizers

Small (integrated design delivers the light weight and small dimensions)

Smart (programming control systems provide precise functions: controlled inlet volume ± 0.1mL; auto stop with time/volume)

Silent (noiseless performance with high energy efficiency)

Strong (more than 150mL/min at 30,000 psi)

CE compliant and RoHS compliant

Small (integrated design delivers the light weight and small dimensions)

Smart (programming control systems provide precise functions: controlled inlet volume ± 0.1mL; auto stop with time/volume)

Silent (noiseless performance with high energy efficiency)

Strong (more than 150mL/min at 30,000 psi)

CE compliant and RoHS compliant

| Specifications | |||||

| Catalog No. | NG-Ti-15K | NG-Ti-20K | NG-Ti-25K | NG-Ti-30K | NG-Ti-45K |

| Flow rate | 150mL/min | 150mL/min | 100mL/min | 100mL/min | 60mL/min |

| Min. Sample | 2mL | 2mL | 2mL | 2mL | 2mL |

| Max. Pressure | 15,000psi | 20,000psi | 25,000psi | 30,000psi | 45,000psi |

| Dimensions(cm) | 75 × 40 × 35 | 75 × 40 × 35 | 75 × 40 × 35 | 75 × 40 × 36 | 75 × 40 × 38 |

| Weight | 40 kg (85 lbs) | 40 kg (85 lbs) | 40 kg (85 lbs) | 45 kg (100 lbs) | 50 kg (110 lbs) |

| Max. Temp. | 80ºC (176ºF) | ||||

| Power | 110V/220V | ||||

| Cleaning | Flush to clean | ||||

| Application | Nano emulsion, fat emulsion, liposome, cell disruption, nano dispersion, deagglomeration | ||||

| Features | Digital display of pressure or pressure gauge | ||||

| Standard Features | |||||

| Parts | Y-type diamond interaction chamber with cooling option | ||||

| Control System | High pressure programming control systems: touch screen, speed control, auto stop control by volume, time, pressure or temperature, settable volume control as low as 1mL, display of flow rate and time, overload protection | ||||

| Pressure Gauge | Electric | ||||

| Inlet Type | 1/4" HP coupling | ||||

| Outlet Type | 1/4" HP coupling | ||||

| Inlet Reservoir | 20mL syringe | ||||

| Outlet Reservoir | 20mL syringe | ||||

| Product Material | 316L stainless steel, tungsten carbide, viton, teflon | ||||

| Material Standard | Sanitary grade, FDA, GMP | ||||

| Warranty | 1 year against any manufacturing defects | ||||

| Option Features | |||||

| Parts | High pressure extruders, homogenizing valves, heat exchanger | ||||

| Control System | Tradition mechanical control: speed, start, stop controls | ||||

| Detector | Pressure gauge, pressure transducer up to 8 optional, temperature transducer up to 8 optional | ||||

| Outlet type | Tri-clamp or luer | ||||

| Heat Exchanger | HPE-100; HPE-150; HPE-200 | ||||

| Liposome Extruder | GOE-200mL; GOE-1000mL | ||||

| Inlet Reservoir | 10mL, 20mL, 50mL, 100mL, 200mL, 500mL syringe, S/S cylinder, jacketed glass cylinder or online | ||||

| Outlet Reservoir | 10mL, 20mL, 50mL, 100mL, 200mL, 500mL syringe, S/S cylinder, jacketed glass cylinder or online | ||||

| Cylinder | Titanium high pressure cylinder (resistant to strong acid and base) | ||||

| Product Introduction and User Guide Video Sharing: User guide of genizer highpressure homogenizers Introduces the structure and operation of the microjet high-pressure homogenizer |

|||||

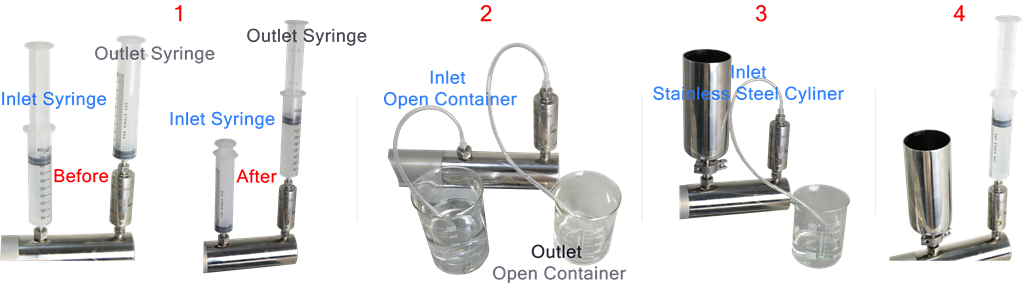

Varieties of Inlet and Outlet for NanoGenizer-titanium

Inlet: syringe; open container; stainless steel cylinder

Outlet: syringe; open container; stainless steel cylinder

Outlet: syringe; open container; stainless steel cylinder

USD

USD

949-932-0294 Los Angeles

949-932-0294 Los Angeles  Nano@Genizer.com

Nano@Genizer.com